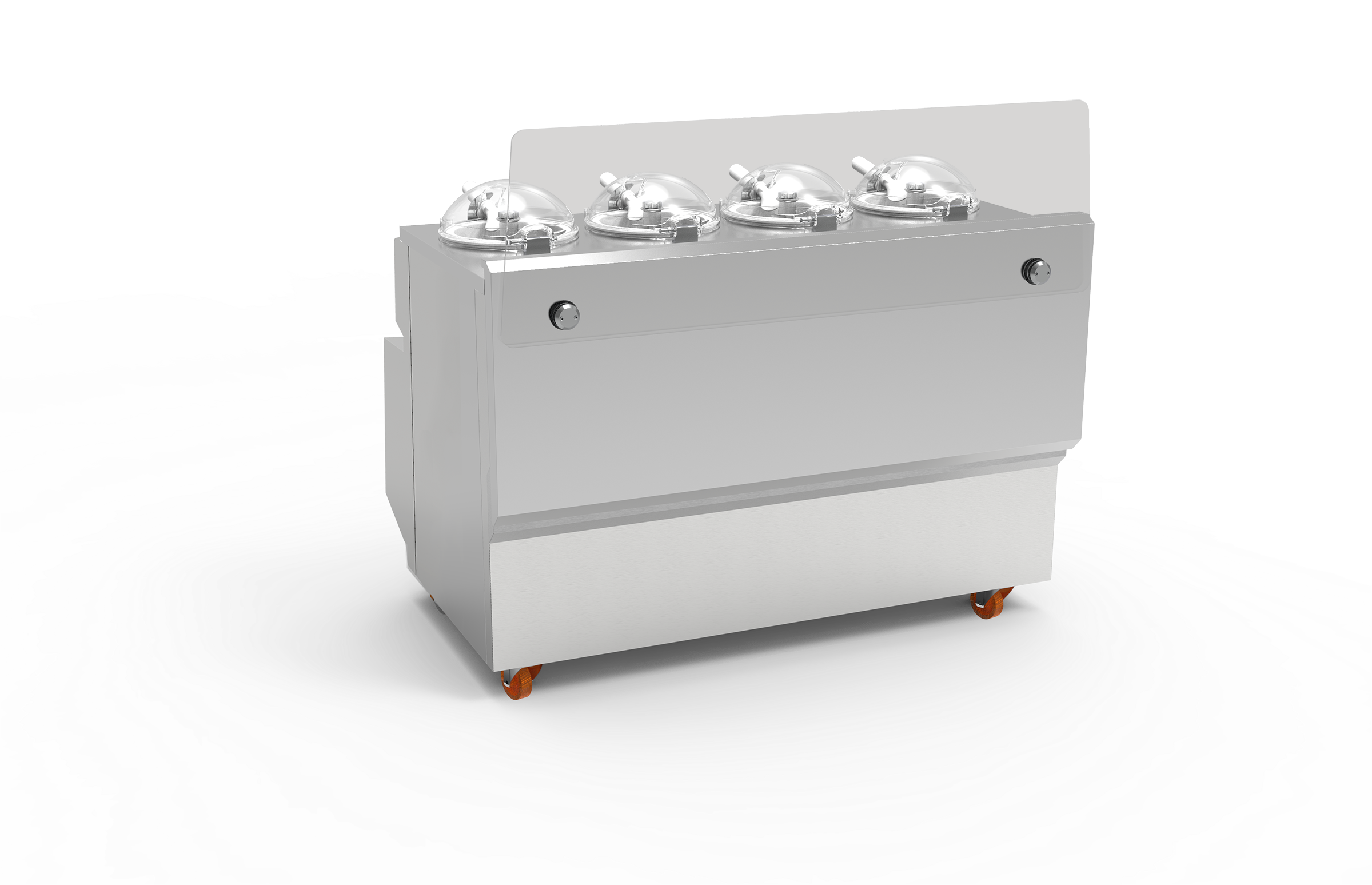

GX4

Hourly production | 12.5 *4 kg/h |

power | 230v/50/1v or 400v/50/3 |

14A,4.8kW or 28A, 4.8kW | |

weight | 340kg |

GX4

Hourly production | 12.5 *2 kg/h |

power | 230v/50/1v or 400v/50/3 |

8A,2.4kW 或 14A,2.4kW | |

weight | 166kg |

CHARACTERISTICS

• Independent production groups with vertical cylinders.

• 7 electronicprograms for the freezing of gelato and slushh; new management of production cycles altlowsigs nificantly reduce energcyonsumption.

• “Night storage” function to maintain the product during long pauses, with considerable energy saving.

• Floor-standing unit; on wheels.

• Air cooling.

ADVANTAGES AND PLUSES

• Eco-friendly natural refrigerant gas and highly efficient refrigeration circuits .

• Enhanced refrigeration system to reduce the freezing and th refill cycles and for a higher gelato consistency.

• Energy-efficient electronic fan motors. • Faster production cycles and refills.

• Possibility to add hard pieces nuts, chocolate, fruit, etc.

• Steel agitators with easily removable scraper blade foer asny cleaning.

• Food-grade rings for perfect thermal insulation of the tanks (patent).

• Transparent lids, enabling the customer to see and follow th freezing process.

• Dedicated spatula(psatent) which, through a practical quick release system, set a new standard of hygiene, protectthineg product against all kinds of contamination. The patrthoef spatula in contact with gelato is placed at a negative temperature in the area of the freezing cylinder, protected through the transparent dome lid. The handle remains outsid the food area, at room temperature, in a defined position fo visual impact of the bench extremely tidy.

• Cleaning system of the cylinders, directly connected to a removable front drain. Internal preparation for a direct discharge into the water mains.

• Safety switch on the lids.

• Maintenance of high levels of hygiene and food safety, cert by Italian University laboratories.